Introduction to Fiberglass Tanks

What Are Fiberglass Tanks?

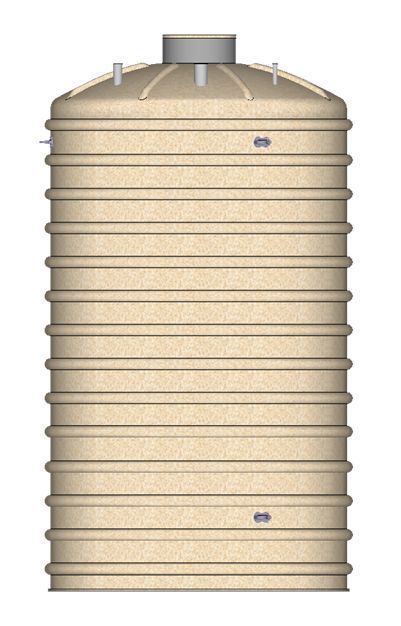

Fiberglass tanks, also known as FRP (fiberglass-reinforced plastic) tanks, are storage containers. Ascertain storage containers made from a composite material consisting of glass fibers and resin. This combination provides exceptional strength, durability, and resistance to environmental factors, making fiberglass tanks ideal for a wide range of applications.

Why Choose Fiberglass Tanks?

Fiberglass tanks are chosen for their unique combination of properties, including being lightweight, corrosion-resistant, and versatile for both above-ground and underground installations. They are widely used across industries such as agriculture, water treatment, chemical manufacturing, and more, due to their ability to meet diverse storage needs effectively.

Key Benefits of Fiberglass Tanks

Lightweight and Easy to Install

One of the most significant advantages of fiberglass tanks is their lightweight nature. Compared to traditional materials like steel or concrete, fiberglass tanks are much easier to handle and install. This reduces labor costs and makes them ideal for locations where heavy equipment access is limited. Additionally, their lightweight design simplifies transportation and off-loading, further lowering overall costs (Tank Depot).

Corrosion Resistance

Fiberglass tanks are highly resistant to corrosion, a common issue with metal tanks that can rust over time. This property ensures that fiberglass tanks maintain their integrity even when storing corrosive substances, extending their lifespan and reducing maintenance costs. Their resistance to corrosion also makes them suitable for harsh chemical environments, where other materials might fail (FRP Mocoat Fiberglass).

Versatility for Above-Ground and Underground Use

Fiberglass tanks are suitable for both aboveground and underground installations. Their resistance to UV rays and environmental exposure makes them perfect for outdoor use, while their durability allows them to withstand the pressures of being buried underground. This versatility makes them a practical choice for a wide range of applications (Tank Depot).

Long Service Life and Durability

Due to their robust construction, fiberglass tanks have a long service life. They are designed to withstand harsh conditions, including extreme temperatures (from sub-zero to 200°F), and can last for decades with minimal maintenance. This durability makes them a cost-effective solution in the long run, as they require fewer repairs or replacements compared to other materials (Design Tanks).

Safety for Storing Potable Water

Fiberglass tanks are non-toxic and do not leach harmful chemicals into the stored water. This makes them safe for storing drinking water and other potable liquids, ensuring that the water remains uncontaminated. Their inert nature also inhibits microbial growth, further enhancing their suitability for water storage (Plastech Services).

Cost-Effectiveness

While the initial cost of fiberglass tanks may be higher than some alternatives, their long service life, low maintenance requirements, and durability make them a cost-effective choice over time. Additionally, their lightweight nature reduces transportation and installation costs, and their resistance to corrosion minimizes the need for frequent repairs (Allied Pumps).

Environmental Benefits

Fiberglass tanks have a lower carbon footprint compared to metal tanks, as they require less energy during production. They are also recyclable, making them an environmentally friendly choice for storage solutions. This sustainability aspect is increasingly important for industries looking to reduce their environmental impact (Tank Depot).

Customizability

Fiberglass tanks can be customized in various shapes and sizes and with different accessories like flanges, ladders, baffles, and insulation. This allows for tailored solutions to meet specific storage needs. For example, tanks can be designed with wall thicknesses ranging from 2.5mm to 6.0mm, and their length and color can be specified to suit particular applications (Unicomposite).

Safety and Compliance

Fiberglass tanks meet industry standards and are non-toxic, ensuring they are safe for a variety of uses. They also prevent leaks and maintain structural integrity, even under pressure. Additionally, they are suitable for fire suppression systems, meeting standards like NFPA 22 for storing large volumes of water (Tank Depot).

Easy Maintenance and Repairs

Fiberglass tanks are easy to repair and require simple checks and cleaning, minimizing downtime. Unlike metal tanks, they do not rust or corrode, reducing the need for frequent inspections. This ease of maintenance further adds to their cost-effectiveness and practicality (Plastic-Mart Blog).

Applications of Fiberglass Tanks

Industrial and Chemical Storage

In industrial settings, fiberglass tanks are used for storing a wide range of chemicals and liquids. Their corrosion resistance is particularly valuable in chemical storage, where exposure to corrosive substances is common. They are also resistant to biofouling, making them suitable for wastewater storage (FRP Mocoat Fiberglass).

Water Storage and Treatment

Fiberglass tanks are extensively used in water storage and treatment facilities. They are ideal for storing both raw and treated water, thanks to their ability to prevent contamination and their durability in various environmental conditions. Their non-toxic nature ensures that stored water remains safe for consumption (Tank Depot).

Agriculture and Aquaculture

In agriculture, fiberglass tanks are used for storing water, fertilizers, and other liquids. Their lightweight and durable nature makes them easy to transport and install on farms. In aquaculture, they are used for fish farming, where their non-toxic properties ensure a safe environment for the fish (Unicomposite).

Fire Suppression

Fiberglass tanks are used in fire suppression systems due to their ability to store large volumes of water and their durability in harsh conditions. They meet standards like NFPA 22, ensuring they are reliable for critical applications (Tank Depot).

Petroleum and Chemical Industries

Fiberglass tanks are widely used in the petroleum and chemical industries for storing various substances. Their resistance to corrosion and ability to handle different temperatures make them ideal for these demanding environments (Unicomposite).

Conclusion

Fiberglass tanks offer a multitude of benefits that make them an excellent choice for various storage needs. Their lightweight design, corrosion resistance, versatility, durability, safety, cost-effectiveness, and environmental friendliness set them apart from other materials. Whether you need to store water, chemicals, or other liquids, fiberglass tanks provide a reliable and efficient solution.

By choosing fiberglass tanks, you not only invest in a durable and low-maintenance storage solution but also contribute to sustainability through their recyclable nature and lower carbon footprint. With their ability to be customized and their proven track record across industries, fiberglass tanks are truly a versatile and forward-thinking choice for modern storage needs.

Recommended Visuals

To enhance the appeal of this blog post, consider adding the following visuals:

-

Image 1: A fiberglass tank installed in an agricultural setting, showcasing its lightweight and durable design.

-

Image 2: A cross-sectional view of a fiberglass tank, highlighting its composite material structure.

-

Video: A short clip demonstrating the installation process of a fiberglass tank, emphasizing ease and efficiency.

Benefits Summary Table

|

Benefit |

Description |

|---|---|

|

Lightweight |

Easier to transport and install, reducing labor and transportation costs. |

|

Corrosion Resistance |

Resists rust and corrosion, ideal for harsh chemical environments. |

|

Versatility |

Suitable for aboveground and underground installations. |

|

Durability |

Long service life, withstands extreme temperatures and harsh conditions. |

|

Safety |

Non-toxic, safe for potable water, inhibits microbial growth. |

|

Cost-Effectiveness |

Low maintenance and long lifespan reduce overall costs. |

|

Environmental Benefits |

Lower carbon footprint, recyclable, less energy in production. |

|

Customizability |

Various shapes, sizes, and accessories to meet specific needs. |

|

Safety and Compliance |

Meets industry standards, prevents leaks, and is suitable for fire suppression. |

|

Easy Maintenance |

Simple repairs and cleaning, minimal downtime. |